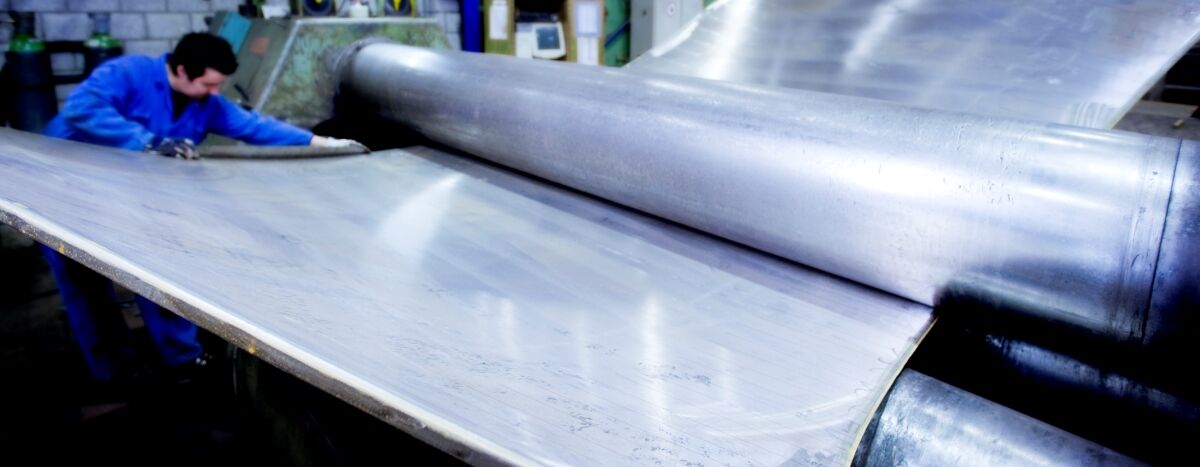

Plate bending

The process of bending a metal sheet into a cylinder or cone

Every material has unique properties that require an appropriate bending technique. Kersten has the necessary expertise and cutting edge machinery to bend plates in both ferrous and non-ferrous alloys to customer-specific hulls, shells, cylinders, conical segments and cones.

Bending metal plates

To bend metal sheets and plates, a complete series plate rollers with three or four rolls are used. We roll the sheets and plates of various material grades with thickness 1 to 150mm and a width of 3-3.5 meters. Sheet and plate thicknesses up to 40mm can be rolled without excess length. To roll thicker plates, excess length is required. Kersten can advise you about how to limit excess lengths to a minimum.

The rolling process is explained in the following animation. It shows the cutting of the blank sheet (including welding preparation), followed by rolling, welding the longitudinal seam, calibration and the application of a 3D cut contour. Having this all carried out by one party saves you time and transport costs.

Another bending techniqe to bend plates is press braking. This technique allows us to bend even thicker plates.

Materials

When a product has specific requirements, such as a specific abrasion or corrosion resistance and/or heat resistance, we at Kersten take this into account. Special alloys such as Creusabro, Hardox, Duplex, Inconel and Clad materials are a solution in such cases. These materials can also be curved in one of our production sites into cylinders or cones.

Special shapes

Kersten receives an every increasing amount of requests to bend materials to a wide variety of shapes: thin and thick walled cones, concentric and eccentric cones, reducers from square to round, and curved segments.